Innovative Design for University Research

/Contract Added Value

In this competitive market place of mechanical and electrical installation and maintenance services, just providing the service and meeting customers’ expectations and contracted service level agreements isn’t always enough. More and more often during tender and bidding processes we are asked to provide examples and quantify the added value we can bring to the contract. This isn’t as easy as it sounds. What we perceive as an everyday example of the service we provide to some, could already include added values to others.

Being able to provide examples of what we do over and above our day job is becoming more and more important so when a chance discussion with one of our engineers occurred with one of our long-standing customers which subsequently led to us providing them with a bespoke solution, we decided to share the story - it’s all about innovation!

Innovation

We encourage our staff and engineers to think outside the box. Most of the tasks we perform every day present little challenge as we are experienced in what we do. When an opportunity arises that requires more thought and perhaps a twist on normal procedure, our experienced staff can normally find a suitable solution, ensuring that they work within health and safety guidelines and following recommended procedures.

We are so adept at solving difficult problems that require an element of innovation that we have included the word in our Mission Statement (read our Mission Statement here).

Innovation was certainly shown by our engineer Richard May who, following a routine planned HVAC maintenance visit, started a conversation with a Research Unit who required equipment that just wasn’t available ‘off the shelf’. Detecting a new challenging opportunity, Richard took the clients problem back to his local office, determined to solve it.

The Challenge

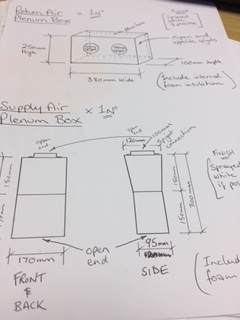

The Research Unit required a laboratory cabinet that could be kept to specific temperature and humidity conditions for certain periods of time. Our team put their heads together and drew a basic plan of how they felt they could build a bespoke system that was mobile, feeding warm or cool air into a cabinet. The temperature requirements were to be set at 29°C for one week and then dropped to 19°C for a further week and then repeated as required. The client also wanted this cabinet in just a few weeks and had a limited budget.

JCW’s Mission

Based on their initial drawings the team began to build their bespoke solution utilizing a portable air conditioning unit, a trolley and some ducting. Over the next couple of weeks, they tested dry air humidifiers and after the first two over running they found one which suitably stabilized the environment. They included a damper to allow for a mix of fresh air and ensured the whole unit was sealed to prevent any interference from external atmosphere.

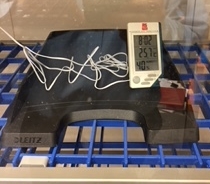

Once complete they commenced testing. Every air conditioning unit can have a variance in the programmed temperatures so every half an hour the team recorded the temperature from the independent temperature display that they installed inside the cabinet. Keeping the cabinet and system in situ to perform this testing was vital before moving it over to the University.

The Result

Following satisfactory testing the temperature controlled laboratory cabinet was ready to be moved to University. Due to the fact that air conditioning units do not necessarily provide a constant temperature and that it is normal for a variance of 3-5° while running, the team were extremely happy to learn, a couple of weeks later, that the variance within the cabinet has only been 1.5°. This was quite a result for the engineers that took a problem, solved it, within a restricted budget and produced a bespoke system that delivered results better than expected, all using their own innovation.

Words from the Contracts Manager, Julian Camp:

“It’s not every day you get an enquiry like this, and one that would have been easy to shy away from due to its non-standard application. However, after considering the requirements of our client, backed with our knowledge and experience of air conditioning systems we were confident we could deliver a solution for the University.

We decided that every aspect of this system needed to be considered, built and tested prior to the final product being delivered. A sealed system with a supply and return air duct with minimal heat-loss, a fresh-air supply duct with control damper and separate humidifiers in the bottom of the cabinet would cover all eventualities and be fully controllable to reach the desired internal temperatures within the cabinet as set by the University. Following 2 weeks of building and testing we ended up with a portable system that operated within 1.5°C of the target temperature. We were delighted with these results as they outperformed our original prediction of 3-5°C.

Working on this project was very enjoyable, and gave us the chance to “think outside the box” and deliver a solution far from any ‘‘Heath Robinson’ design. The system has now been installed at the University and has been running successfully for several weeks. We continue to offer support and advice following the completion of these works and welcome the next challenge.

Conclusion

Offering innovation to our customers is something we do every day, whether it’s performing a simple task which saves engineer time or combining experience and skill that subsequently cause less disruption and expense to our client to building a bespoke cabinet which can be warmed or cooled for preset periods of time. This is what builds lasting relationships with our clients, makes our job more fulfilling and gives our engineers and staff a sense of pride.

Testimonial

“I’ve been really impressed with the commitment and enthusiasm shown by the team at JCW as we worked on achieving a system that worked. The engineers appreciated the requirements of the project from the outset, and also responded helpfully when unexpected challenges arose.“ University Research Unit

To find out more about what we do, take a look at our blog page, full of industry insight and useful information.